28 April 2024

Reduce the risk of propeller shaft bearing damage

DNV has published a piece of technical news, focusing on how to reduce the risk of aft propeller shaft bearing damage.

In January 2022, DNV published technical news drawing attention to the latest trend related to propeller aft shaft bearing damage on vessels, typically 10 years or older. This trend continues, and many of the reported damages are encountered on installations using environmentally acceptable lubricants (EALs) and/or involving a history of operation with a contaminated lubricant.

Table of Contents

Key challenges in safeguarding the aft bearing

In many cases, there are inherent challenges and/or gaps in detecting the early signs of aft shaft bearing damage (hereafter referred to as the aft shaft bearing) with the aim of minimizing the risk and severity of the damage:

- Older vessels using EALs exhibit inferior load shaft bearing capability in some extreme transient operating conditions with accompanying high local oil film pressure in the shaft bearing (illustration 1)

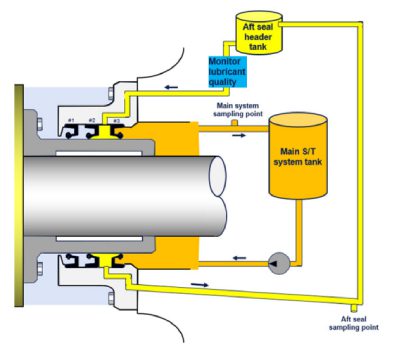

- Aft sealing system lubricant quality is not monitored to ensure suitability for continued use, in particular where an EAL is used. Degradation of lubricant quality may negatively affect the inner shaft sealing ring condition, consequentially risking contamination of the stern tube lubricant system.

- Continuous operation with incomplete propeller immersion leads to the downward bending of the shaft because of eccentric propeller thrust forces. This runs the risk of edge loading in the aft part of the shaft bearing and consequential local overheating (illustration 2).

- Abrupt increase in aft bearing temperature before the high-temperature alarm is activated, particularly at lower operating temperatures.

Seawater lubricated shaft line to reduce emissions

The shipping industry has to get rid of the oil-lubricated shaft line and replace it with one lubricated by seawater.

Ship Nerd

How to reduce the risk of aft shaft bearing damage

Some suggestive measures to enhance the design and aft shaft bearing monitoring, and hence to reduce the risk of damage:

- Consider the use of a double-sloped shaft bearing – to further optimize the load distribution and enhance the design and operating margins in continuous and extreme transient conditions (illustration 3).

- Provide means of warning for the high rate of rise of the aft bearing temperature and incomplete propeller immersion – to be used as early signs for operators to undertake proactive actions.

- As a proactive measure to safeguard the inner shaft sealing ring(s) and stern tube lubricant condition, monitor and regulate the lubricant (EAL) quality in the aft sealing system to fulfill the oil makers’ and seal makers’ recommendations for continued use (illustration 4).

- Increase the EAL viscosity to the next higher grade above design specification for EAL application on older installations (for vessels with applicable DNV Rules older than July 2019). Vessels with applicable rules as of July 2019 or later will need new approval if the design oil type or viscosity grade is changed (ref DNV EAL news Oct 2019).

- Investigate and undertake prompt actions if main stern tube system lubricant analysis reveals elevated levels or an increasing trend of water content, Total Acid Number (TAN), bearing and/or shaft material wear elements, etc.

TMON(Oil lubricated, +) notation – new prescriptive solution

The enhanced tail shaft monitoring class notation qualifier TMON(Oil lubricated, +) was offered by DNV in July 2022. This optional notation serves to further minimize propulsion safety risk and prevent costly equipment failure, building on the benefits of the existing TMON class notation.

The TMON(Oil lubricated) and Shaft align class notations are prerequisites for TMON(Oil lubricated, +), thus incorporating key measures stated in the section above to minimize the risk of damage.

The notation is offered for newbuildings; however, it may also be considered as part of upgrades of existing ships. Applicable rules are included in Pt.6, Ch.9, Sec.4 of the DNV Rules for ships, as of July 2023.

Key benefits of TMON(Oil lubricated, +) for fleet owners and managers:

- Enhanced aft-bearing performance in normal and extreme operational conditions.

- Detection and mitigation of the early signs of undesired operational and performance conditions.

- Safeguarding of the stern tube lubricant condition by proactive monitoring of aft sealing system.

- Positive implications on commercial operations.

Recommendations

To reduce the risk of propeller aft shaft bearing damage, DNV recommends that customers review and consider the recommendations in this news.

By opting for the TMON(Oil lubricated, +) notation, operators have the possibility to enhance the design as well as pick up early warning signs to prevent issues and minimize the risk and severity of bearing damage.

Source: DNV

See Also

Are you already sailing a hybrid ship and wondering what the next decade will bring? Or maybe you’re interested in investing in a hybrid ship and want more insight? Let’s dive into the hottest trends in hybrid ships and find ways to save fuel while increasing vessel performance.

7 hybrid ship trends that everyone needs to know about

Let’s dive into the hottest trends in hybrid ships and find ways to save fuel while increasing vessel performance and attractiveness.