28 November 2024

Offloading Onboard Captured Carbon – We are not ready yet

A landmark study by the GCMD on offloading onboard captured carbon dioxide identifies low port readiness as there are key barriers to large-scale commercialization.

- Infrastructure and procedures for handling captured carbon dioxide (CO₂) at ports are currently inadequate

- Defining clear pathways to offload, utilise, and/or sequester CO₂, is crucial for large-scale commercialisation of onboard carbon capture and storage

Table of Contents

Concept

A recent study commissioned by the Global Centre for Maritime Decarbonisation (GCMD), in collaboration with Lloyd’s Register and ARUP, has identified low port readiness as a major hurdle bottlenecking the adoption of Onboard Carbon Capture and Storage (OCCS) system as a practicable decarbonization solution. Whilst the technologies required for offloading onboard captured carbon (CO₂) exist at high levels of maturity, safe operationalization of captured carbon (CO₂) transfer by trained personnel has not been demonstrated.

Offloading Onboard Captured Carbon

The report, titled “Concept study to offload onboard captured carbon (CO₂),” found that while a limited number of ports possess the infrastructure to offload liquefied CO₂ (LCO₂), they are primarily designed to handle food-grade CO₂. The higher purity standards that accompany this use limit the interoperability of facilities to handle onboard captured CO₂.

The study examined over 10 planned LCO₂ related infrastructure projects worldwide. Located near, or with transport links from, CO₂-emitting industrial clusters, these projects are likely to handle much larger volumes of captured carbon (CO₂) than that from OCCS systems; port infrastructure needed for offloading, storing and transporting onboard captured carbon (CO₂) will likely need to be integrated with these projects for economies of scale. However, as many of such projects remain in the concept phase and have not reached the Final Investment Decision (FID), ports have not proceeded with offloading infrastructure investments. This chicken-and-egg dilemma highlights the overall infancy of the carbon value chain.

Furthermore, introducing LCO₂ offloading into already complex port operations will likely impact port efficiency and operational performance. The need for additional buffer zones to address the safety concerns of LCO₂ handling and storage will also add to existing space constraints at ports and terminals.

The Gap in the Carbon Capture Value Chain

This 9-month-long study aims to address a gap in the onboard carbon capture value chain. OCCS has recently gained traction as a potential interim solution to help international shipping meet IMO’s emissions reduction targets, with potential deliberations at future Marine Environment Protection Committee (MEPC) sessions. While achieving emissions reductions through OCCS hinges on successfully integrating a shipboard-compatible system within space constraints, equally important is addressing the fate of captured carbon (CO₂) by establishing its utilisation or sequestration pathways.

Wind-to-Wake Concept for Shipping Decarbonization

Shipping decarbonization goes beyond the norm. Get up to speed with Wind-to-Wake, the updated method of lifecycle assessment for green fuels.

Ship Nerd

This study complements GCMD’s Project REMARCCABLE (Realising Maritime Carbon Capture to demonstrate the Ability to Lower Emissions) by addressing the feasibility of OCCS as a practicable, end-to-end solution at scale. For OCCS systems to be operationally feasible, the industry needs to develop a collaborative ecosystem to enable the value chain for managing captured carbon (CO₂).

By systematically considering the needs of the entire value chain, this study evaluated 4 concept configurations of offloading infrastructure from a possible 162 scenarios, identified the operational standards and safety guidelines for handling LCO₂, developed models for the quantification of costs for scaled-up infrastructure, articulated manpower competency frameworks for offloading operations, and analysed the potential regulatory scenarios needed to address the current uncertainties surrounding LCO₂ offloading from OCCS.

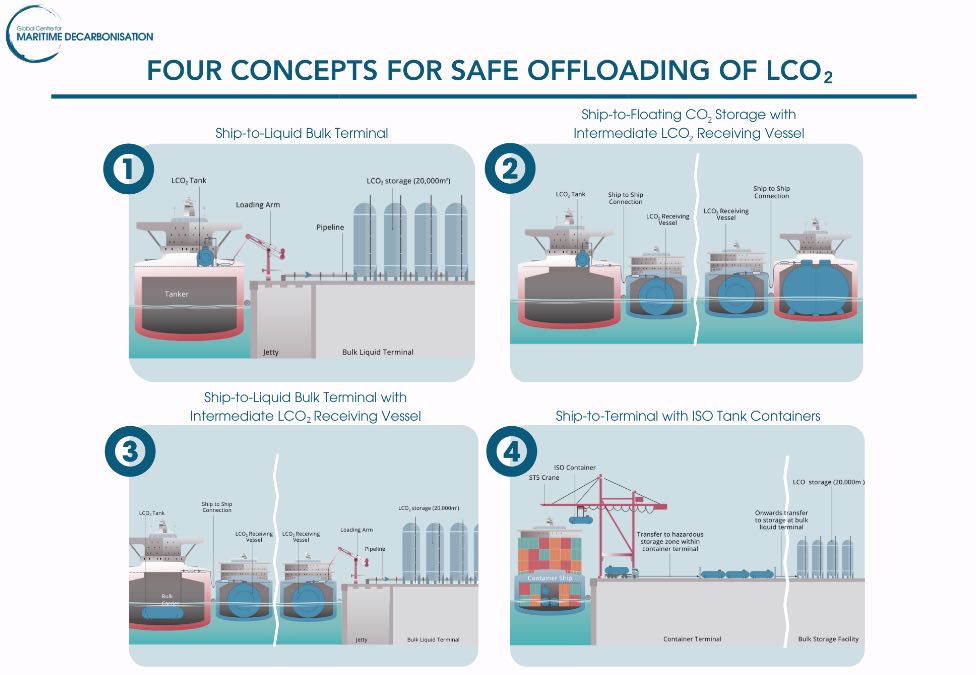

Concepts for Safe Offloading of LCO₂

One of the key considerations is to examine how LCO₂ can be offloaded safely to the appropriate infrastructure.

The study determined that captured carbon (CO₂) in its liquefied form (LCO₂) is likely the most efficient and cost-effective option for onboard storage and transport. Based on this, the study shortlisted 4 concepts covering key offloading modalities, such as Ship-to-Ship and Ship-to-Shore, serving as building blocks that can be combined to cover a wider range of offloading concepts. (Please see below for the infographics on these four concepts).

In ranking the operability of these concepts, the study identified Ship-to-Ship and Ship-to-Shore transfers using an intermediate LCO₂ receiving vessel as the most promising modalities for offloading at scale, with captured carbon (CO₂) eventually sequestered or used as feedstock for manufacturing synthetic fuels.

Ship-to-Terminal transfer of captured CO₂ stored in ISO tank containers was identified to be more compatible at smaller scales and for end uses that require higher grades of CO₂. This modality of transfer is also most compatible with existing port infrastructure and therefore easier to pilot today.

Safety Considerations for Handling LCO₂

Handling LCO₂ onboard presents a unique set of safety challenges not commonly encountered when handling fuels in shipping. The study offers an in-depth examination of hazards, such as asphyxiation and toxicity, if a leak or a loss of containment takes place.

Unique to CO₂ is the evaluation of its storage at conditions near its triple point, where the gaseous, liquid and solid phases of CO₂ co-exist. Storage at or near the triple point is sensitive to impurities, and minor changes in temperature and pressure can lead to a phase change from liquid to solid CO₂, leading to hazardous situations, such as blockage in pipes and build-up of pressure.

To address these hazards, a series of safety studies, including a Hazard Identification (HAZID) of offloading, Simultaneous Operations (SIMOPS) and a coarse Quantitative Risk Analysis (QRA), were conducted and mitigation measures and emergency response procedures articulated for handling LCO₂.

Views from the Contributors

“While pilots have successfully demonstrated numerous capture technologies onboard ships, it is still uncertain how captured carbon on merchant ships can be safely offloaded, and what the rest of the value chain looks like. This study sheds light on these challenges, and highlights recommendations to holistically address these concerns for parties interested in advancing OCCS / LCO₂ offloading concepts.”

Professor Lynn Loo, CEO, GCMD

“The maritime industry requires a comprehensive understanding of the safety and operational challenges posed by all emissions reduction technologies. This study, which focused on port readiness and considerations for the safe handling and offloading of LCO₂, addresses some of the gaps that exist in the carbon capture value chain and will support industry stakeholders in making informed investment decisions around carbon capture solutions and the creation of regulatory and operational guidelines.”

Nick Brown, CEO, LR

“As a result of the study, it has been promising to see how transferable existing CO₂ industrial knowledge is to an offloading application. Arup brought together energy and maritime capabilities to outline the concepts for onboard captured carbon (CO₂) offloading and develop how this new process can practically and safely integrate into busy port environments. We look forward to seeing the technologies and implementation develop into effective marine decarbonisation solutions.”

Robert Cooke, Design Lead, Arup

To access the full study findings, please download the report here.

See Also

Wah Kwong is one of Hong Kong’s largest shipowners. Shanghai Qiyao Environmental Technology Co. Ltd. (QIYAO ENVIRON TEC) is a subsidiary of Shanghai Marine Diesel Engine Research Institute. They all have signed a cooperation agreement to study the feasibility of installing carbon capture and storage (CCS) units on existing ships to meet 2030 CII targets.

Feasibility Study: Installing Carbon Capture & Storage

BV, Wah Kwong and Qiyao will study the feasibility of installing carbon capture and storage units on existing ships for 2030 CII targets.