28 November 2024

New PSV Conversion into Cable-Laying Vessel – Q3 2024

IT International Telecom Marine has chosen Vard for the conversion of the platform supply vessel (PSV) IT Infinity into a cable-laying vessel.

Table of Contents

Conversion Concept

Subsea cable network provider IT International Telecom Marine has chosen Norwegian shipbuilder Vard to convert the platform supply vessel (PSV) IT Infinity into a cable-laying vessel.

The PSV was built at Vard Brattvaag and delivered to Volstad Maritime in 2008 under the name Volstad Princess. SD Standard Drilling bought the vessel in 2017 before it was sold to IT in 2021 for $10.3m and renamed it to its current name. Now, the vessel has gone full circle and will return to Vard for conversion.

“We are proud that IT chose VARD as their partner for this conversion. We will now use our core competence and long experience in the design and construction of advanced Cable Laying Vessels to meet IT Telecom`s needs in the market. This project demonstrates VARD’s strength with our fully integrated value chain and it confirms our position in the aftermarket.”

Wilhelm Eggesbø, SVP Vard Services, VARD

Green cable-laying vessel for increased HVDC cable demand

XLCC has completed the concept design of a cable-laying vessel to meet the increasing demand for HVDC cables.

Ship Nerd

Vard Electro is involved in the project through the installation of cable and new switchboards as well as updating existing electrical systems. Vard Interiors is delivering HVAC solutions. The conversion will be carried out in the same yard where it was built and will be delivered in the third quarter of 2024.

“IT is pleased to partner with Vard on the conversion. Returning to the yard where she was built provides unique efficiencies, decreasing time to market for an industry in dire need of these specialized ships,”

Louise Thivierge, General Manager, IT

More about Cable-Laying

Specialized Vessels

Despite all the impressive technology that goes into cable manufacture today, underwater cables have actually been around for over 150 years. Indeed, the very first transatlantic telegraph cable laid between 1854 to 1858. Note that, it was capable of sending entire messages in a matter of minutes from Ireland to Newfoundland. Of course, back then these cables were laid haphazardly by slow-moving steamships.

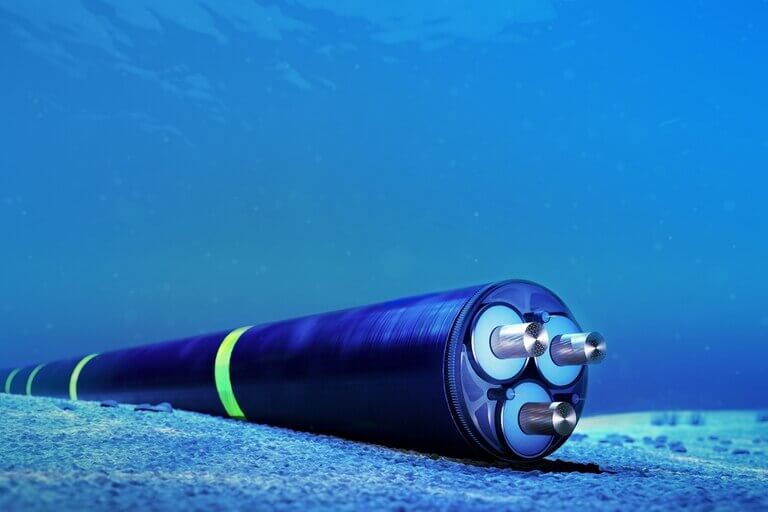

Today, the application will take place by specialized vessels with unique rotary sections for cable storage and deployment. Built with special mooring and propulsion systems which enable them to reduce motion when operating in both shallow and deep water. The interior of these unique vessels is equally intriguing. The most notable is the way the entire center of the ship dedicates to the cable-laying process.

There are thousands of feet of tether for the ROUVs in addition to the underwater cables. Therefore, vast sections of the ship completely dedicate to storage space. Additionally, the vessels have specially equipped sections from which the movements of the ship cable laying devices and ROUVs can coordinate via remote control.

As we continue to see an increase in the demand for offshore power no doubt these massive cable-laying vessels will become a more frequent site on oceans and lakes all around the world.

Challenges

However, this process is still susceptible to a variety of unique challenges and problems. To reduce some of these dangers, the installation team will plow the seabed and bury the cables. Fishing vessels and anchoring ships still remain a danger to even the most insulated cable designs. A single disturbance or one misplaced anchor and entire island nations could lose power and communications for days at a time.

There have been reports of sharks and other marine predators biting the undersea cables potentially putting holes in the insulation that may lead to corrosion down the line.

Since repairing the cable involves dredging up the damaged section and carefully replacing it at sea, one can only hope technology will find a way to render these threats far less damaging.

The reason why underwater cables are so expensive

Why underwater cables are so expensive? Get up to speed on underwater cables construction, application, recycle while also advanced cable laying vessels.