28 November 2024

Air Lubrication 101: A Comprehensive Introduction by QueSeas

Air lubrication system is an ever-growing technology for commercial shipping as a promising method to reduce ship hull resistance.

Table of Contents

Background

On the road to green shipping, numerous design concepts have been proposed to improve efficiency. Such a design concept is the air lubrication system (ALS). Air lubrication system is an ever-growing technology that was developed back in the 1950s by the US Navy, firstly as a radiated noise reduction system. The main idea is that by producing bubbles on the hull and around the propeller, the warship would eventually become silent acoustically, and less detectable by other ship’s sonic radar. Later, the concept of air lubrication became popular for commercial shipping as a promising method to reduce ship hull resistance.

The ship resistance can be deconstructed into three main components: frictional resistance, form resistance, and wave resistance. Frictional resistance is the most dominant contributor to this equation, especially for low-speed vessels, which can reach even 80% of the total resistance. Since frictional resistance depends on the wetted surface area of the ship, air lubrication can reduce this frictional drag, considering there is no big change in the hull form.

In 2018, to comply with ship emissions and the EEDI phase III levels, IMO recognise air lubrication as Category B-1 “Innovative Energy Efficient Technology” (MEPC.1/Circ. 815 (2018)).

More Air Lubrication Systems on cruise ships

World’s largest cruise company to extend installation of air lubrication on ships to reduce fuel consumption and carbon emissions.

Ship Nerd

Air Lubrication Technology

The general idea is that by injecting compressed air beneath the hull of the ship, an air layer is formed and therefore the direct contact of the ship’s wetted surface area with the water is reduced. The skin frictional resistance is therefore reduced, and consequently, the fuel consumption is also decreased.

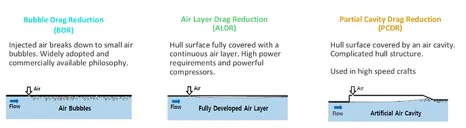

There are three main categories of air lubrication technology until now:

Bubble Drag Reduction (BDR)

This is the most widely adopted mechanism. It injects air into the bottom of the ship’s hull which breaks down into micro-bubbles, around 0.1 mm. By bubble addition to the liquid, the liquid density is decreased and hence the Reynolds number reduces. There are many commercially available systems, such as CMES-Tech Air Layer Enenrgy Saving System (ALESS), Mitsubishi Air Lubrication (MALS), SAMSUNG Heavy Industries SAVER System, Silverstream System, and Foreship Air Lubrication System (Foreship ALS).

Air Layer Reduction (ALDR)

Fully developed air layer from a continuous thin air layer. Hence, the hull surface is fully covered with a continuous air layer. This setup involves high power requirements and extensive capacity compressors.

Partial Cavity Drag Reduction (PCDR)

Air cavity that covers the hull surface. It is more popular among high-speed vessels. The most popular commercial solution is Damen’s Air Chamber Energy Saving (ACES) System.

Components

Air lubrication system normally consists of piping, pneumatic and control systems, and air dispensers. Local stress concentrations for the additional openings, piping, and ventilation might need to be re-arranged and thoroughly evaluated for the ALS installation. A typical ALS arrangement for an LNG carrier includes:

- Air supply unit installed in the bosun store or compressor motor room, such as;

- 2 x screw compressors (water cooled) with VFD,

- 1 x Air Reservoir

- 1 x FW cooler;

- 2 x SW cooling pumps;

- 2 x FW cooling pumps;

- Marine Prevention System;

- Air injectors installed on duct keel and recess space in No. 2 Ballast Tank (S) & (P);

- Hydraulically driven remote valves;

Performance

Full-scale sea trials have been carried out since 2002, and a general overview is that ships could achieve a net power saving upon to 3-7%. However, the performance depends on the weather conditions, speed, type of the ship, and the hull form.

- Is the electrical energy consumed by ALS compensated with the energy saving when the vessel is in actual operation (after 2-3 years)?

- What are the maintenance and operational costs of the system?

- Does the draught affect the efficiency of the ALS?

- Can ALS be installed on all commercial vessels such as oil tankers or bulk carriers?

- Is it a good investment for retrofit?

Of course, numerous questions may arise, and it is obvious that there is no straightforward answer. Moving into the era of sustainability, it is certain that newer technologies will be introduced. Therefore, research and proper information will be our “stepping stones” to correct decisions and operations.

Retrofit vs newbuild? 45% of ships today will not comply

Carbon regulations targeting older, less efficient ships. Is it wiser to retrofit an existing vessel to improve its ratings, or replace it with a newbuild?

Ship Nerd

For further discussion about this subject, and other critical maritime questions related to technical management, green shipping, and more, visit QueSeas.

About QueSeas

QueSeas is a game-changing free online wiki database, inspired by the immense success of Stack Overflow, that aims to revolutionize the maritime community. With its user-friendly interface, extensive category coverage, and active community of experts, Queseas provides a central hub for maritime professionals to connect, share knowledge, and collaborate. By promoting accessibility and fostering a spirit of collaboration, Queseas empowers mariners worldwide to navigate the vast ocean of information, enabling them to propel the maritime industry towards unprecedented levels of excellence.

See Also

Wärtsilä has successfully completed an inline shaft generator retrofit on the ‘Berge Toubkal’, a cape-size bulk carrier owned by Singapore-based Berge Bulk.

The retrofitted shaft generator will also provide power to an air lubrication system installed at the same time. Air lubrication technology reduces the frictional resistance of the vessel by creating a carpet of microbubbles that coats the majority of the flat bottom of a vessel’s hull. The microbubbles, measuring 1–3mm in diameter, are generated by air release units (ARUs) at the bottom of the hull.

First inline shaft generator retrofit for the maritime industry

Wärtsilä has successfully completed an inline shaft generator retrofit on the ‘Berge Toubkal’, a cape-size bulk carrier owned by Singapore-based Berge Bulk.