28 November 2024

Ballast Water Treatment Systems: Up to speed

This is everything you need to know to get up to speed with Ballast Water Treatment Systems (BWTS). Why? How it works? Types available, Pros & Cons.

Concept

A ships main purpose is to carry a multitude of cargo and transport it from port A to B. Note that a specific draught comes with each ship and its loading conditions. However, when the vessel discharges the cargo, the draft will increase. Hence, affecting the manoeuvrability and stability of the vessel. That is where ballast comes into play.

Definition

Ballast is any additional solid or liquid onboard a vessel. Its scope is to increase the draught, change the trim, and regulate the stability or to maintain the stress load within acceptable limits.

But why bother with ballast?

Environmental Concerns

Ballast water (BW) contains a variety of invasive aquatic species such as; marine and coastal plants from different regions of the world. If taken up in one place and released in another, some organisms may survive and prosper in their new environment. These “non-native species” can have a serious ecological, economic and public health impact on the receiving environment.

Therefore, to combat the problem of invasive species from ballast water, the IMO adopted measures in 2004. The International Convention for the Control and Management of Ships’ Ballast Water and Sediments. On 8 September 2017, the convention entered into force.

So what are the regulations?

Regulation

B-4 and D-1

Regulation B-4 stipulates that vessels performing ballast water exchange should do so in the open ocean. At least 200NM from the nearest land and in waters at least 200m in depth. It is effective as a voluntary measure in certain regions since 2009. Regulations B-4 and D-1 establish a standard for BW exchange to minimize the spread of invasive species.

The D-1 regulation is based on a simple principle. Organisms and pathogens contained in ballast water taken on board from coastal waters will not survive if discharged into deep oceans or open seas. This is due to the different temperatures, salinity, and chemical composition of open seas.

B-3 and D-2

Regulation B-3 requires vessels to perform BW management using a type-approved treatment system. Note that such a system shall meet the performance standard defined in Regulation D-2.

D-2 standard specifies the maximum amount of viable organisms applicable to discharge, including specified indicator microbes harmful to human health.

Compliance with D-2 seems to be achievable only by the use of a BW treatment system or port management system. In general treatment systems that comply with the standard have to get approval from IMO.

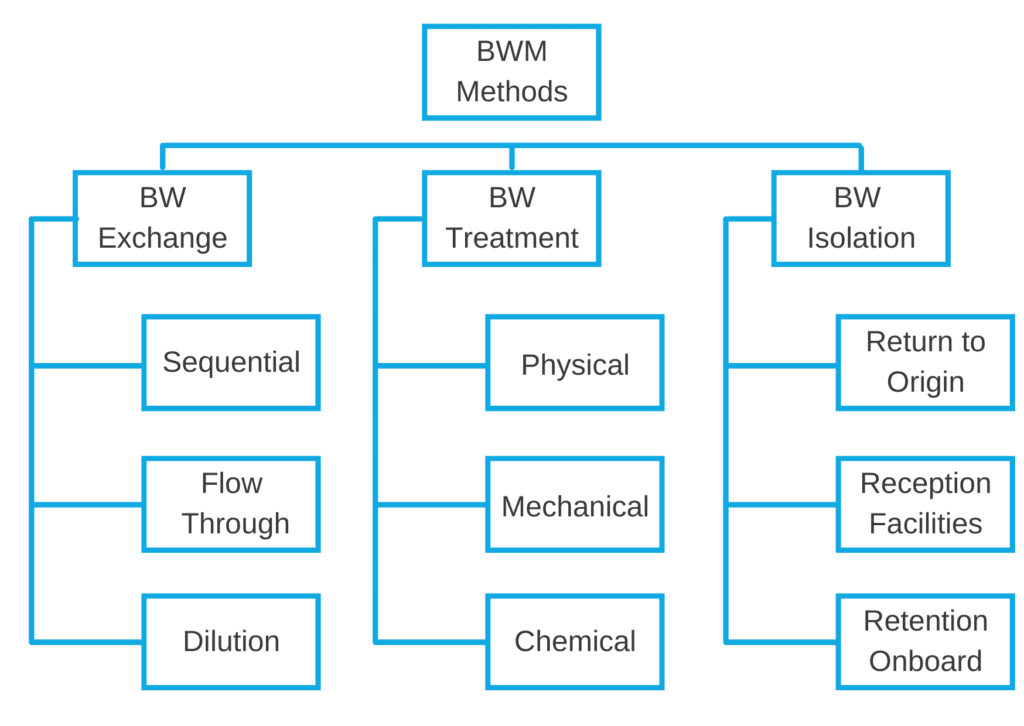

Ballast Water Management Methods

Complying with IMO regulations may come by various management methods. Depending on the different criteria, the shipowner should choose the ideal one.

Ballast Water Exchange (BWE)

BWE is a process that involves the substitution of water inside the vessel’s ballast tanks. This method has become obligatory by the IMO, while the following ways comply with B-4 and D-1 regulations.

- Sequential: BW tank is first emptied and then refilled with replacement ballast water to achieve at least a 95% volumetric exchange. Thus, reducing the chances of having remaining organisms at the bottom of the tanks. Later, new water can fill the tank.

- Flow-through: Replacement ballast water pumps into the tank. Water can freely flow through overflow or other arrangements to achieve at least 95% volumetric exchange. Moreover, the water should pump 3 times the volume of each tank to meet the D-1 standard.

- Dilution: Replacement ballast water fills through the top of its tank. Concurrently, water discharges from the bottom at the same flow rate, maintaining a constant level in the tank throughout the exchange operation. Like Flow-through, 3 times the tank volume should pump through the tank. Commonly 2 ballast pumps are used, one acts as a filling and the other as a suction pump.

Ballast Water Treatment (BWT)

Various BWT systems are available to ensure compliance with the prescribed regulations. Understanding the pros and cons of each technology is important to make the best decision.

There is no BWT solution suitable for all vessel types, sizes, and operating conditions. Therefore, to assess the operational limitations of BWT technologies, there are 3 primary water characteristics to keep in mind; salinity, temperature, and ultraviolet transmittance.

Most BWT systems utilize a two-step process: physical separation (pre-treatment) followed by disinfection (main treatment). Disinfection involves the use of chemical, physical or a combination of treatments to destroy or neutralize microorganisms in BW.

Physical separation

Physical separation refers to the removal of solid material, including suspended particles and larger microorganisms.

–Hydrocyclones

Ballast water rotates at high velocity in a conical section to remove heavy particles. But, since many microorganisms have similar densities with water, they remain unseparated.

Hydrocyclones arrangement is usually in parallel to treat higher flows because of their limited capacity. However, the high-pressure drop across many units means that the available pressure from the pump may be a limitation.

–Coagulation/Flocculation

Refers to the use of chemicals to trigger the formation of larger masses. Hence, having easier filtration from the ballast water. However, this process is time-consuming and requires a large tank and thus is less common than the other separation principles.

–Filtration

Filtration is the most common method of pre-treatment. Generally with a mesh size smaller than 50 μm, to remove larger particles and microorganisms. For instance, the candle, basket, and disc filter types are the most common.

Mechanical separation

–UltraViolet Light

UV systems are the most popular option in the market. Specifically, UV radiation attacks organisms outright or destroys their ability to reproduce.

Note that, efficiency depends on the turbidity of the ballast water as this can limit the transmission of UV radiation.

They are suitable for any vessel but preferably for those with small ballast capacity and flow rates of up to 1000m3/hr. Typically, RO-RO vessels, container ships, offshore supply vessels, and ferries.

Pros

- Easy to install

- Efficient

- Independent from salinity

- Minimal safety

Cons

- Huge power consumption

- UV lamps issues

–Heat Treatment

This treatment involves heating the BW to reach a temperature that will kill the organisms. The waste heat from the engine and the backup boiler is an efficient method. On the contrary, the installation of a separate system may provide the required heating.

Pros

- Efficient

- Energy saving

Cons

- Timely to make organisms inactive

- Increase corrosion in tanks

–Ultrasound

Ultrasound or sonication technology has the use of a secondary treatment option. Ultrasonic energy produces a high-energy ultrasound to kill the cells of the organisms in ballast water. Useful as a pre-treatment to aid in the overall treatment process.

–Magnetic field treatment

The magnetic field treatment uses coagulation technology. This is a treatment system for aquatic organisms, micro-organisms, and microbes. Particularly, magnetic powder is fed to the ballast water during filling. Water agitates and magnetic separation then occurs.

Pros

- No chemicals for sterilization

- Aqueous ingredients in ballast water are not changing

- Re-treatment of the discharging water, neutralization, etc., is not necessary

Cons

- Magnetic field treatment is complete once the coagulation process finishes

–Electric pulse

Small-scale experiments are performed by applying electrical voltage (15-45 kV with a pulse duration of 1µs). Large energy sources are necessary for systems capable of treating large volumes of ballast water.

Pros

- Environmentally friendly

- Easy installation

Cons

- Impact on the operations of the ship

- Crew proper training required

- Technology is still under investigation

Chemical separation

–Biocides

The addition of chemicals to kill or inactivate a variety of organisms found in ballast water. It is an attractive treatment technology because of its ease of application. Simply add a biocide to the ballast tank and allow it to react for a specified period. However, the biocides used must be effective on marine organisms. Also readily degradable to prevent discharge water from becoming toxic in nature. A low-cost one-way treatment with convenient installation. A disadvantage can be corrosion development.

- Oxidizing biocides: general disinfectants such as chlorine, bromine, and iodine used to inactivate organisms in the ballast water.

- Non-oxidizing biocides: a type of disinfectant which interferes with the reproductive, neural, or metabolic functions of the organisms.

–Deoxidizing

It involves bubbling nitrogen or other inert gases into ballast water to reduce the oxygen content. The purging/removing oxygen from the water tanks will make the organisms asphyxiate. It generally takes approximately 2-4 days for the inert gas to asphyxiate the organisms. Thus, this method is usually not suitable for ships having short transit times. Cost-efficient and environmentally friendly method. Corrosion is not an issue for that method.

–Chlorine

A strong oxidizing agent. Easy to add to ballast tanks through a chlorinator installed in-line. Before discharging ballast water, it would be necessary to remove the free excess chlorine through dichlorination. However, environmental risks apply, so treating that water with chlorine needs further investigation.

–Chlorine dioxide

A strong disinfectant. The main concerns with chlorine dioxide are the cost and the possible environmental toxicity of by-products. Chlorine dioxide is toxic to aquatic organisms. But under normal dosing conditions, it will have declined to very low levels before release. Very effective for ballast water treatment with low power consumption.

–Ozone

A very powerful oxidizing agent which destroys viruses and bacteria. It dissolves, decomposes and reacts with other chemicals, and kills organisms present in water. An efficient one-way treatment, independent of salinity. An issue can be the expensive configuration of the device as well as the corrosion that may arise.

Ballast Water Isolation (BWI)

BWI is a port-based treatment. Transferring ballast water to an offshore facility and then carrying out the necessary treatment. Note that, the size of the treatment facility would depend on; the number, timing, and type of ships passing the particular port. For instance, Valdez Marine Terminal in Alaska has had one treatment facility for decades to remove residual hydrocarbons from dirty ballast water.

This method allows ports to offer ship operators a ballast water treatment at short notice. Hence, ensuring minimal downtime for the vessel.

Moreover, the IMO approved such designs which are primarily for port use. At a glance, the system receives ballast water from inbound vessels and treats it to the IMO D-2 standard and eliminate potentially invasive marine micro-organisms.

Nerd thoughts

The interaction of high-salinity, open-ocean water is intended to kill the low-salinity non-native species typically originating from coastal regions. While open-ocean waters also contain organisms and pathogens, they are generally sparsely distributed and deem to pose a lower risk of invasion. However, ballast water exchange has a limit on the effectiveness and poses safety risks for the vessel. Thus, IMO regards this as an intermediate solution that will phase out over time. Most vessels will eventually require to install an onboard ballast water treatment system that meets the standard described in BWM Convention Regulation D-2.

References:

See also: Propellers: Up to Speed