28 November 2024

4 new methanol engines to accelerate transition to sustainable fuels

Wärtsilä will introduce another four methanol engines to its portfolio, setting a new industry benchmark with the broadest methanol engine portfolio currently on the market.

Table of Contents

Concept

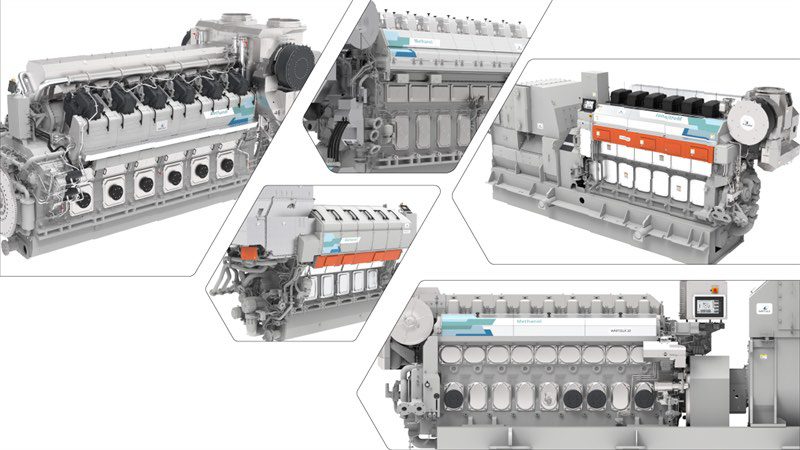

Technology group Wärtsilä will introduce another four methanol engines to its portfolio, setting a new industry benchmark with the broadest methanol engine portfolio currently on the market. In addition to the Wärtsilä 32 methanol engine launched last year, Wärtsilä will add the Wärtsilä 20, Wärtsilä 31, Wärtsilä 46F and Wärtsilä 46TS to its portfolio of engines capable of operating with methanol fuel.

Methanol Engines Upgrades

Methanol is one of the primary alternative fuel choices for the shipping industry to achieve net zero carbon emissions by 2050. For example, ‘green’ methanol can be produced using renewable energy sources and carbon capture technology, making it a sustainable and carbon-neutral option. It can also be rather easily integrated into existing shipping operations as it can be stored and transported using the existing infrastructure for conventional liquid fuels.

Renewable production can make methanol a viable fuel for 2030

Renewable production is needed to overcome the pricing, availability, and carbon accounting of methanol as a viable fuel for 2030 energy transition.

Ship Nerd

Throughout the Wärtsilä diesel engine portfolio, covering both new engines, as well as those currently in operation, Wärtsilä is developing the corresponding methanol retrofit capabilities. Methanol upgrades are either available or under development for the Wärtsilä 31, Wärtsilä 32, Wärtsilä 46F, Wärtsilä 46TS and Wärtsilä ZA40S engines. Whereas the Wärtsilä 20 engine family can be ordered with methanol combustion capabilities. By making these engines capable of running on methanol fuel, Wärtsilä has expanded its methanol offering to a wide range of vessel types across the marine industry.

Views from the Maker

“Decarbonisation is front and centre to our strategy going forward, and the development of engines capable of running on future fuels is crucial to that. Wärtsilä takes an innovative approach to supporting the marine industry’s transformation to more sustainable operations, and this broad range of methanol engines emphasises this,”

Roger Holm, President of Wärtsilä’s Marine Power business

“Wärtsilä is backing its extensive experience with strong investments in developing new fuel-flexible technologies and products. We recognize that it is vital for ship owners to have maximum flexibility and to keep options open as the industry navigates the uncertain pathway to net zero, and we are working hard to deliver this operational flexibility. Our track record is already very solid, and this expanded engine portfolio adds to both our accomplishments and our long-term commitment to the maritime industry,”

Stefan Nysjö, Vice President of Power Supply, Wärtsilä Marine Power

Wärtsilä is one of the few marine engine builders with extensive experience in methanol engines, having converted the first of four engines on the ferry Stena Germanica in 2015. Last year, the Wärtsilä 32 Methanol engine and MethanolPac storage and supply system were launched, becoming one of the first commercially available solutions for using methanol as a fuel in the maritime industry. The Wärtsilä 32 Methanol engine has received type approval certificates from several classification societies.

The four new methanol engines will be available for deliveries at different points from 2025 onwards.

Source: Wärtsilä

See Also

MAN Energy Solutions has signed a Conversion Commitment Agreement with Seaspan Corporation (Seaspan), a global leader in containership ownership and management in collaboration with Hapag-Lloyd, one of the leading global liner shipping companies. Under the terms of the Agreement, MAN PrimeServ, MAN Energy Solutions’ after-sales division, will deliver 15 methanol engines retrofit solutions for the conversion of vessels powered by individual MAN B&W S90-type fuel-oil-powered engines from the Seaspan and Hapag-Lloyd fleets to dual-fuel ME-LGIM methanol engines capable of running on green methanol. This Agreement includes 45 optional methanol engines retrofit solution. Each conversion can provide a CO2 reduction of 50.000–70.000 Tonnes each year, when operating on green methanol.

Agreement for 15 methanol engines retrofit solution signed

MAN to deliver 15 methanol engine retrofit solutions for Seaspan and Hapag-Lloyd vessels for dual-fuel propulsion on the way to decarbonization.