28 November 2024

How to use the new biofuels in shipping

What is the safe operation of ships using biofuels and/or biofuel blends and how to comply with international regulations when using these fuels?

Table of Contents

Concept

The use of biofuels or biofuel blends is one of many ways to comply with the IMO’s strategy on the reduction of GHG emissions from ships, and DNV has seen an increasing interest in these new fuels. Hence, we aim to clarify the regulatory status and other considerations regarding the usage of such fuels.

MEPC 79 – New amendments & IMO GHG Strategy

What are the new amendments and GHG strategy that resulted from the IMO MEPC 79? This is everything you need to know.

Ship Nerd

Classification societies receive many requests regarding the safe operation of ships using biofuels and/or biofuel blends and how to comply with international regulations when using these fuels. Below, there is a summary of regulatory issues, safety, and operational aspects.

Types of biofuels

FAME

FAME (Fatty acid methyl ester) is produced from vegetable oils, animal fats, or waste cooking oils by transesterification, where various oils (triglycerides) are converted to methyl esters. This is the most widely available type of biodiesel in the industry and is often blended with regular marine diesel.

International standards: ISO 8217:2017, EN 14214, ASTM D6751, EN 590.

BTL

BTL (Biomass to liquid) fuels are synthetic fuels that are produced from biomass by means of thermo-chemical conversion using the Fischer-Tropsch process or the methanol to-gasoline process. The final product can be chemically different from conventional fuels such as gasoline or diesel but can also be used in diesel engines.

International standards: EN 16709, EN 15940

HVO/HDRD

HVO/HDRD (Hydrogen vegetable oil / Hydrogenation derived renewable diesel) is the product of fats or vegetable oils – alone or blended with petroleum – refined by a hydrotreating process known as fatty acids-to-hydrocarbon hydrotreatment. Diesel produced using this process is often called renewable diesel to differentiate it from FAME biodiesel. HVO/HDRD can be directly introduced in distribution and refueling facilities as well as existing diesel engines without any further modification.

International standards: ASTM D 975

Currently, FAME is the most prominently used biofuel in marine applications. It is either used in blends with traditional petroleum fuels or as 100% biofuel

Effect of Biofuels on GHG regulations

The Maritime Safety Committee has invited all relevant IMO bodies to assess their respective involvement in the human element within their remit. Hence, report back to the committee with a view to devising an outline for a holistic approach on the human element, taking into account resource and budgetary implications within the IMO. In this regard, HTW 9 invited member states and other interested parties to submit papers to HTW 10 in February 2024.

Model training courses

IMO model courses intend to assist instructors in developing training programmes for seafarers as per the International Convention of Standards of Training, Certification and Watchkeeping for Seafarers (STCW), 1978. The model courses are subject to regular review to ensure that they are consistent with the current IMO instruments and reflect best practices and modern technologies.

HTW 9 validated a large number of model courses, as there was a backlog due to time constraints in the remote sessions of the last two years.

The following model courses are now validated and will be published soon:

- EEDI and EEXI

The EEXI and EEDI only consider the so-called tank-to-wake approach, meaning that only the carbon content of standard reference fuels that the vessel is designed for are considered. For that reason, the usage of biofuels has no effect on the EEXI or the EEDI. - CII (Carbon Intensity Index)

In view of IMO DCS reporting as well as the CII calculation methodology – as per the 2022 SEEMP Development Guidelines, Resolution MEPC.346(78), and the CII Calculation Methods Guidelines, Resolution MEPC.352(78) – in case of fuel types not covered by the guidelines, the conversion factor Cf is to be obtained from the fuel oil supplier and supported by documentary evidence.

Any non-standard approach in the determination methodology of tank-to-wake emissions for biofuels is subject to acceptance by the vessel’s flag administration as well as the RO handling the IMO DCS and CII verification on behalf of the flag, where an addition to the list of fuel types used and applicable conversion factors needs to be reflected in the SEEMP Part II.

In case of acceptance of the flag state administration, the usage of biofuels, also in form of blends with traditional petroleum fuels, will have a significant impact on the reduction of the CII value - EU MRV

As per Regulation (EU) 2015/757, in the case of alternative fuels, the monitoring plan shall contain “the methodologies for determining the emission factors, including the methodology for sampling, methods of analysis and a description of the laboratories used, with the ISO 17025 accreditation of those laboratories, if any”.

It is worth noting that Directive (EU) 2018/2001 (EU RED II), Annex V, Part C provides a methodology for greenhouse gas emissions from the production and use of transport fuels, whereas per point 13, the CO2 emissions of the fuel in use shall be taken to be zero for biofuels and bioliquids.

The proposed method for calculation of the CO2 emission factor for biofuel and biofuel blends should be included in the ship’s MRV Monitoring Plan along with an addition to the list of fuel types used and method for determination of fuel density, with the revised plan being subject to acceptance from the Accredited Verifier.

SEEMP (Part I, II, III) – Everything you need to know

What is SEEMP? From the year 2023, the ships subject to the CII rating will have to develop a SEEMP Part 3 (III) on or before 31 December 2022.

Ship Nerd

Biofuels’ effect on NOx regulations

On 10 June 2022, the Marine Environment Protection Committee approved Unified Interpretations (UIs) to Regulation 18.3 of MARPOL Annex VI simplifying the use of biofuels on board ships. It is now generally assumed that marine diesel engines certified in accordance with MARPOL Annex VI Regulation 13 should be permitted to use most liquid biofuels without the challenge of emission testing on board.

There is no need to apply for an exemption according to MARPOL Annex VI Regulation 3 for testing the use of biofuels, and there is no need to follow the equivalency procedure under Regulation 4 of Annex VI to the MARPOL Convention.

A self-check according to the Onboard Verification Procedure (to be found in the engine-specific Technical File) would be sufficient to demonstrate that “biofuels do not cause an engine to exceed the applicable NOx emission limit”.

Appendix 1 contains more details on the application of Regulation 18.3 of MARPOL Annex VI.

Technical observations & challenges on board

These are some of the possible consequences of the use of biofuels:

- Microbial growth: Bacteria and mold may grow, causing filters and piping to clog.

- Oxygen degradation: Biodiesel could form deposits in piping and engine, compromising operational performance.

- Low temperature: The higher cloud point may lead to the clogging of filters at lower temperatures.

- Corrosion: Some types of hoses and gaskets could degrade, leading to loss of integrity, and interact with some metallic material to form deposits.

- Possible degeneration of rubber sealings, gaskets, and hoses: Important to verify that these components can be used together with biofuel.

- Conversion: When switching from diesel to biofuel, fuel filters can become clogged.

Source: DNV

See Also

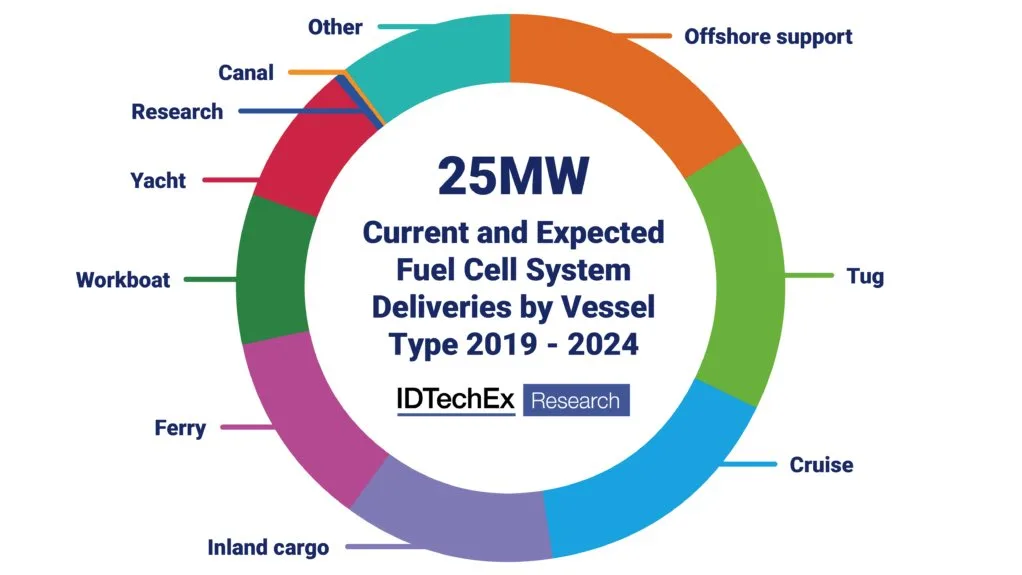

Rapid adoption of green fuel cells in marine markets

IDTechEx released a report outlining the adoption of green fuel cells in marine markets, running on alternatives such as green hydrogen and ammonia, as some of the most promising solutions.