28 November 2024

World’s 1st LCO2 carrier intended for CCUS by Mitsubishi

Japanese shipbuilder Mitsubishi Shipbuilding has concluded a contract with compatriot shipping company Sanyu Kisen. They will construct a demonstration test ship to transport liquefied carbon dioxide (LCO2 carrier).

Concept

The Enoura Plant of MHI’s Shimonoseki Shipyard & Machinery Works will construct the vessel. Specifically, with completion and delivery scheduled for the second half of fiscal 2023.

The construction of the ship will serve for technology development and demonstration to realize high-volume CO2 transport. Note that it is part of New Energy and Industrial Technology Development Organization (NEDO) project initiatives.

Upon building completion and delivery, the Engineering Advancement Association of Japan (ENAA) will charter the test ship from Sanyu Kisen. Hence, carry out research and development and demonstration tests for establishing LCO2 ship transportation technology.

Contribution

Under consignment from ENAA, there are three additional project partners; Kawasaki Kisen Kaisha (K-Line), Nippon Gas Line, and Ochanomizu University. Thus, they will accelerate the R&D of LCO2 transportation technology and contribute to cost reduction of CCUS technology. Additionally, establish safe, long-distance, and large-scale transportation of LCO2. In the demonstration project, the partners plan to use the vessel to collect operational data; under various loading conditions and in various weather and sea conditions.

Design

LCO2 carriers used in the food industry have previously been constructed and operated in Europe and Japan. Although, this newbuild will be the world’s first LCO2 carrier intended specifically for; carbon capture, utilization, and storage (CCUS), according to Mitsubishi Shipbuilding.

Specifically, Mitsubishi Shipbuilding will be in charge of all aspects from the ship design through construction. This includes the cargo containment system development. Note that in September 2021, the shipbuilder received approval in principle from Bureau Veritas for the LCO2 carrier cargo tank system.

With a tank capacity of 1,450cbm, the new demonstration test vessel will feature dimensions of 72 x 12.5m.

Carbon Capture Solution

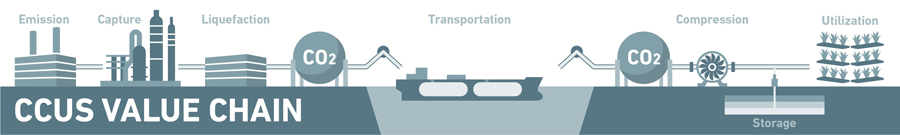

CCUS is garnering attention today as an effective means of achieving a carbon-neutral society. Because CO2 emissions sites are often in distance from the carbon utilization or storage sites, demand will expectedly increase for LCO2 carriers which can transport their cargo safely and economically.

Through the experience from constructing the world’s first LCO2 carrier built specifically for CCUS, MHI Group said it will strengthen its current strategic business focused on the energy transition.

The company will also continue its dedication to developing and providing the technologies relating to LCO2 carriers necessary for CCUS value chain building, to contribute to CO2 ecosystem development.

Source: MHI